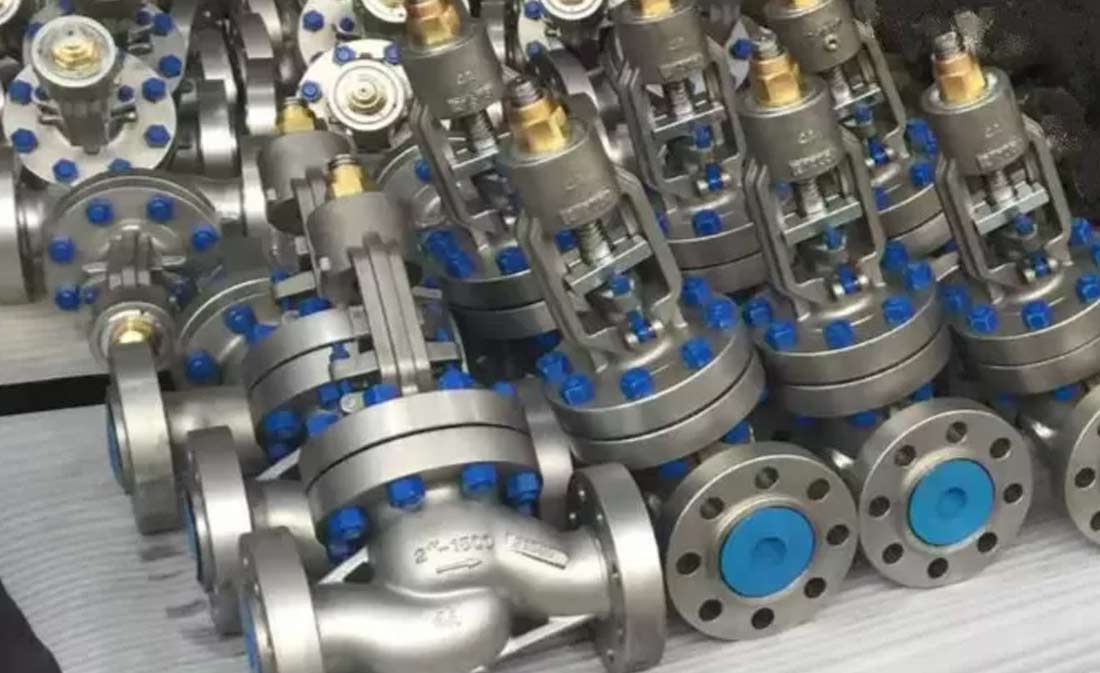

Monel 400 Forged Valves

Monel 400 Forged Valves Specification

| Specification | Details |

|---|---|

| Material | Monel 400 (UNS N04400) |

| Type | Forged Valve (Ball, Gate, Globe, Check, etc.) |

| Pressure Rating | ANSI 150, 300, 600, 900, 1500, 2500 (depending on size and design) |

| Size Range | 1/4" to 4" (varies by valve type and pressure class) |

| Temperature Range | -425°F to 1000°F (-254°C to 538°C) |

| End Connections | Flanged (RF, FF), Threaded, Socket Weld, Butt Weld |

| Face-to-Face Dimension | As per ANSI B16.10 (varies by valve type) |

| Flange Rating | ANSI B16.5, DIN, JIS (depending on application) |

| Face-to-Face Length | As per ASME B16.10 (standard face-to-face dimensions) |

| Testing Standards | API 598, ISO 5208, ASME B16.34 |

| Leakage Class | Class IV or Class VI (depending on valve type) |

| Flow Coefficient (Cv Value) | Varies by size and type of valve |

| Body Material | Monel 400 (UNS N04400) |

| Seat Material | PTFE, PEEK, or other elastomers (depending on valve type) |

| Bonnet Material | Monel 400 (UNS N04400) |

| Stem Material | Monel 400 or Stainless Steel 316L |

| Design Standard | ASME B16.34, API 602, ISO 9001 |

| Pressure Test | 1.5 times the working pressure or as per manufacturer |

| Corrosion Resistance | Excellent resistance to corrosion in seawater, acids, and alkaline environments |

| Applications | Marine, chemical processing, power generation, oil and gas, aerospace |

| Certification | CE, UL, ISO 9001, PED (if required) |

| Material Composition | ~66% Nickel, 30% Copper, with trace amounts of Fe, Mn, Si, C, and S |

| Mechanical Properties | – Tensile Strength: 70-85 ksi (485-585 MPa) – Yield Strength: 30-60 ksi (205-415 MPa) – Hardness: 95 HRB (approx.) |

| Welding | Compatible with common welding processes (TIG, MIG) |

| Surface Finish | Typically Ra 3.2 µm to 6.3 µm (depending on application) |

| Resistance to Stress Corrosion Cracking (SCC) | Excellent, particularly in marine and chloride-rich environments |

| Fatigue Strength | Excellent, well-suited for dynamic loading applications |

Equivalent Grades

| STANDARD | UNS | WNR. | JIS | BS | GOST | AFNOR | EN |

| Monel 400 | N04400 | 2.4360 | NW 4400 | NA 13 | МНЖМц 28-2,5-1,5 | NU-30M | NiCu30Fe |

Chemical Properties

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Monel 400 | 0.30 max | 2.00 max | 0.50 max | 0.024 max | 28.00 – 34.00 | 2.50 max | 63.00 min |